Products

| Non-standard laser marking and laser welding |

Laser marking and optical fiber laser marking machine

Mainly by laser, vibration lens, playing card is composed of three parts, the fiber laser marking machine production laser, beam quality, the output center for 1064nm, the whole life in about 100 thousand hours, compared with other types of laser marking is longer, the efficiency of electro-optic conversion is more than 28%, compared with other types of laser marking the conversion efficiency of 2%-10% machine has great advantages in energy saving and environmental protection and other aspects of outstanding performance.

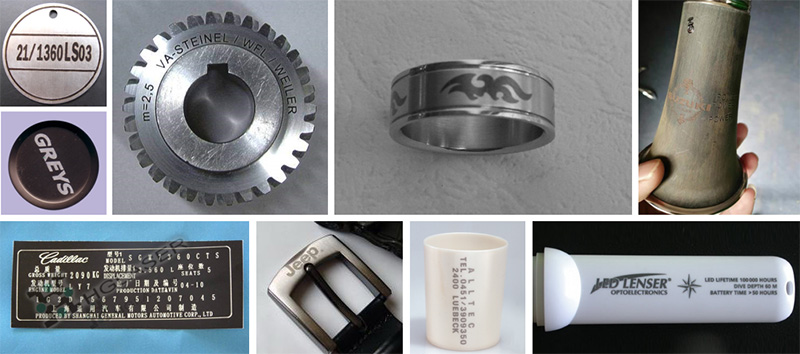

Used in electronic components, integrated circuit (IC), electrical appliances, mobile phone communications, hardware, tool accessories, precision instruments, watches, jewelry accessories, auto parts, plastic buttons, building materials, PVC pipe. Laser marking - software function introduction 1 free design has the pattern to be processed; 2 support TureType font, single line font (JSF), bitmap font (DMF), one-dimensional bar code and DataMatrixdeng and other two-dimensional code; 3 flexible variable text processing, processing in real time to rewrite the text, you can directly read and write text files and Excel files; 4 powerful nodes to write functions and graphics editing functions, can be carried out curve welding, cutting and calculation; 5 supports 256 pens, you can set different processing parameters for different objects; 6 compatible with the commonly used image format (BMP, JPG, GIF, tag, PNG, TIF, etc.); 7 compatible with commonly used vector graphics (AI, DXF, PLT, etc.); 8 commonly used graphics processing functions (grayscale conversion, black and white map conversion, network processing, etc.), you can carry out 256 grayscale image processing; 9 strong fill function to support ring filling; 10 a variety of control objects, the user can freely control the system and external device interaction; 11 open a variety of language support functions, can easily support the language of the world; Laser marking - Case picture Laser marking machine is to use a laser beam in a variety of different material surface marked with a permanent mark. Marking the effect is through the surface of the material to expose the material, so as to carve out the exquisite patterns, trademarks and text

Automatic laser marking Full automatic laser marking machine, laser marking machine control principle of marking products most divided into vector and matrix marking, laser marking vector not by marker to form characters, but by drawing lines to achieve laser marking. For vector graphics, points, lines, circles and arcs are the basic patterns and characters of the characters. Full automatic laser marking machine line drawing function consists of two parts: first, find the coordinates two endpoints of a straight line, and then convert it into position coordinates galvo respectively control two, different working position from the start point to the end mirror at the same time to control the fiber laser marking machine marking. Through the control of the full automatic laser marking machine marking, draw a straight line and point is the most easy to achieve, but also the fastest operation, so the circle and arc is also achieved through a straight line. If the straight line as a very short section of the string to draw, you can draw a circle. The ends of these strings are on the circumference of the circle. However, if the number of line segments is too small, that is, the 10 degree of each chord is corresponding to the arc, then the string generated by the circle is not smooth. So in order to make the number of circular smooth strings the more the better, the number of the string more calculation speed and processing speed will be reduced. This needs to be adjusted according to different marking requirements. The general method can apply to draw circle draw arc, but with different circle, as a part of the circle, in use the corresponding arc angle can be drawn. Vector character marker Zhicheng full automatic laser marking machine adopts vector markup characters, such as a pen to write, can be seen as the laser pen, marking according to the strokes, the difference is that the laser marking by the principle of proximity, and try to make the stroke continuously, and not in accordance with the order of strokes character to mark, in order to improve the speed. Laser welding and laser welding machine

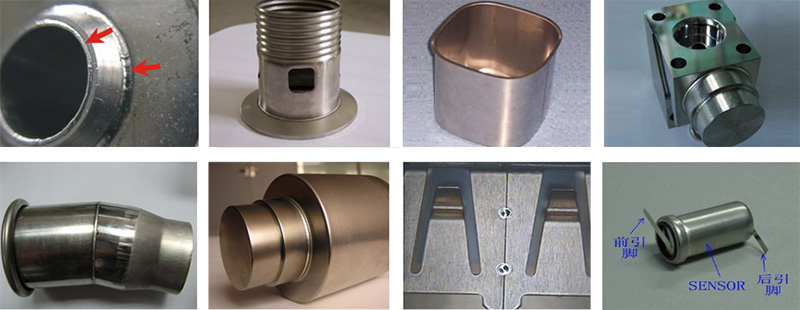

Laser welding Laser welding can be achieved by continuous or pulsed laser beam, the principle of laser welding can be divided into heat conduction welding and laser welding. The power density is less than 104~105 W/cm2 for heat conduction welding, the welding depth and welding speed; power density is greater than 105~107 W/cm2, the metal surface heated into concave "hole" function, the formation of deep penetration welding, with high welding speed, high aspect ratio features. The heat conduction of laser welding principle: laser radiation heating surface to be machined, the surface heat through the heat transfer oriented internal diffusion, by controlling the pulse width and energy, peak power and repetition rate of the laser parameters, the molten pool, the formation of specific. Laser welding machine used for gear welding and metallurgical sheet welding is mainly related to laser welding. General use of continuous laser beam material connected with deep penetration laser welding, the welding physical metallurgy processes and the electron beam is very similar, that is the energy conversion mechanism is through the "hole" (Key-hole) to complete the. At sufficiently high power density laser irradiation, the material is evaporated and formed into a small hole. This is full of steam holes like a blackbody, almost all the energy absorption of the incident beam, the cavity of the equilibrium temperature of around 2500 0C, the high temperature heat from the cavity wall passed out, the molten metal surrounds the cavity around. The hole filled with high temperature steam generating material wall continuous beam evaporation in the hole walls surrounded by molten metal, the liquid metal is surrounded by solid material (welding in most conventional welding process and laser energy transmission, firstly deposited on the workpiece surface, and then rely on transfer to internal). The steam pressure of the liquid flowing outside the hole wall and the wall surface tension and the hole cavity continuously generated and keep dynamic equilibrium stalemate. The beam is constantly in the small hole, the material in the small hole in the continuous flow, with the beam moving, the small hole is always in the steady state of flow. In that way, the molten metal of the small hole and the wall of the hole moves forward with the leading beam, and the molten metal is filled with the gaps left by the small holes and then condensed, and the welding seam is formed. All of this happened so fast in the process, make it easy to reach several meters per minute speed of welding. Laser welding - Case pictures  |

中文版

中文版 English

English